20.10.2022

20.10.2022

Femtosecond lasers in processing polymers

Polymers is a classification of composite materials that are widely used in various microelectronics devices such as semiconductors, electrical components, displays, image sensors, and lithium-ion batteries. At the base level, these materials are plastic, inert chemically, non-conductive and non-magnetic, and unreactive in many environments. Further development of the material allows it to be light weight with high mechanical strength, heat and chemical inertness, and great abrasion resistance.

Given polymers’ characteristics, the demand for the material, and its development to suit various applications, is continuously growing. Hence, new production and processing methods using technologies that are superior to traditional ways are required to keep up with the demand. One of these methods include laser processing which matches complex modern problems with unique properties and unconventional possibilities.

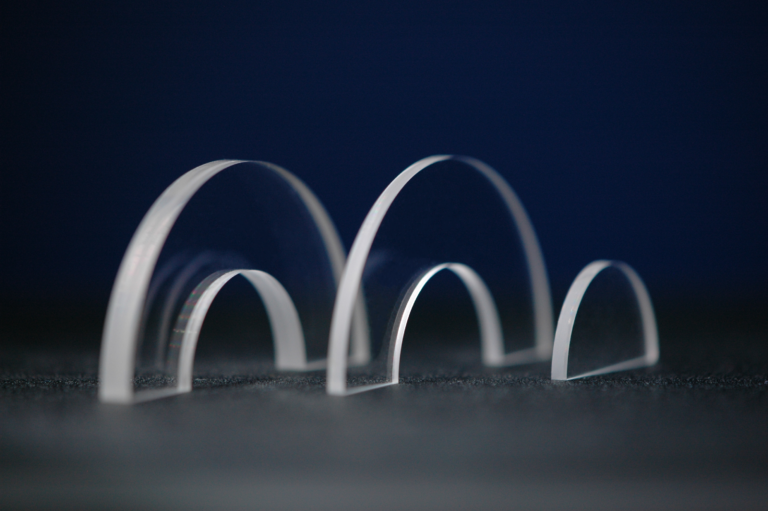

One of the primary benefits of laser processing technology is its high-precision cutting with small kerf widths which enables the creation of complicated geometries in 3D. Another essential benefit is that it minimizes the heat-affected zone (HAZ) with a combination of demanding industrial processing at high speeds. Although the use of lasers is a business-accepted solution, the choice of the laser system varies for different production challenges.

For composite materials, including polymers, it’s difficult or even impossible for conventional lasers to perform layer-by-layer homogenous material removal. It’s also a tough task to cut carbon fiber- and glass fiber-reinforced polymers. These cannot be overcome by continuous-wave and long-pulse lasers, and processing using non-laser technologies is not an option.

Due to the sensitivity of the material, processing at high speeds is only possible with high-power femtosecond lasers. On the bright side, using femtosecond lasers brings several advantages:

- High-quality processing with high throughput can be achieved for different materials such as glass fiber-reinforced plastic, glass-reinforced epoxy laminate, or carbon-reinforced composite.

- The HAZ and carbonization are greatly reduced.

- The differences in material properties between fibers and polymers become less relevant under ultrashort pulses. This is shown by the results obtained in Fluence’s Ultrafast Application Lab. Composite materials of varying melting points, decomposition temperatures, thermal conduction, and absorption (bandgap) behave almost as homogenous materials.

- Each dielectric becomes metallic nearly instantly under the interaction of ultra-high intensity of the femtosecond laser pulse. If the laser fluence remains optimal for a proper ablation mechanism, the quality of the surface will be ideal.

- Each dielectric becomes metallic nearly instantly under the interaction of ultra-high intensity of the femtosecond laser pulse. If the laser fluence remains optimal for a proper ablation mechanism, the quality of the surface will be ideal.

- The flexibility of changing laser parameters also enables material-selective interaction. For instance, the removal of only the polymer matrix and leaving fibers uncovered is possible.

To determine the laser best suited for different applications, various laser parameters must be investigated. This can be done with Jasper, Fluence’s all-in-one solution. It includes all-fiber technology and non-SESAM usage.

This all-fiber femtosecond laser can be used in an industrial setting 24/7/365, which is vital for a fast-paced, successful business. Jasper was constructed to provide a turn-key alternative to free-space systems, helping reduce ownership costs by minimizing the need for maintenance over its many years of operation.

Jasper is also one of the few femtosecond solutions providing tunability of up to four wavelengths. Its software enables the user to select: the fundamental wavelength (1030 nm), second harmonic (515 nm), third harmonic (343 nm), or fourth harmonic (257 nm). Additionally, pulse duration can be adjusted from 270 fs to 8 ps. The temporal pulse structure (burst mode) can be selected as well.