21.04.2021

21.04.2021

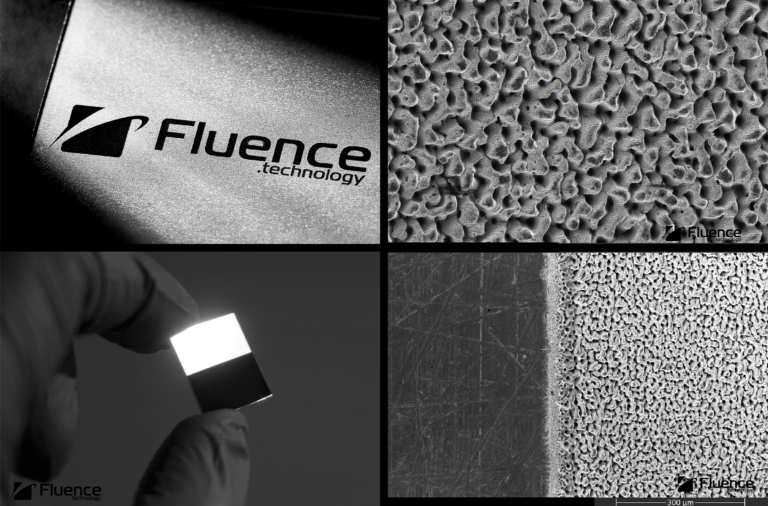

High-contrast laser marking of metals

Fast and efficient systems for marking and tracking products with their serial numbers and countries of origin are the backbone of modern industry. Nowadays even an egg comes with a number determining the farm it came from!

While in some cases inks and paints are a sufficient solution, the industrial and medical applications require something more. Paints and coats are susceptible to mechanical damage. Put on the tools, they wear down during cleaning or are scratched while used. Moreover, in some cases, it is of paramount importance to avoid potentially toxic chemicals, and those are often ingredients of paints. For example, when marking the medical devices and implants it is extremely important to keep in mind the interaction between the mark and the living tissue.

Luckily, there is a simple solution to the above. We can alter the surface of the material itself instead of putting something on top of it! That’s when the laser marking comes in.

Using a femtosecond laser gives a few interesting advantages. In contrary to a more widely spread continuous-wave laser, the femtosecond laser allows us to mark practically any metal like titanium, tungsten, or stainless steel with unmatched precision and speed. Secondly – the marking modifies the surface of the material itself leaving no alien substances. That means that laser marking is safe for medical uses. Thirdly – such marks are lasting and it’s difficult to remove them.

To top it all, the laser marking gives smooth, precise edges and high contrast even on the smallest of scales. This is possible thanks to characteristic surface nanoscale features that appear only under ultrashort pulse irradiation. It makes the surface antireflective only due to the nanotopography. An useful tool for that might be Fluence’s compact Jasper Flex laser, created with industrial applications in mind. This femtosecond laser will help you get the highest marking quality available!

Jasper Flex has maximum pulse energy of 30 µJ at up to 1 MHz repetition rate and 30 W of average power. One thing that makes it really special is Fluence’s unique technology of truly all-fiber, SESAM-free oscillator. Together with a fiber preamplifier, it creates a monolithic, robust construction. It’s capable of working in industrial settings regardless of shocks and vibrations.

Contact us for more information!