01.03.2023

01.03.2023

FLEXIBLE PRODUCTION TOOLS IN ALL IMPLANTABLE MEDICAL DEVICE MATERIALS

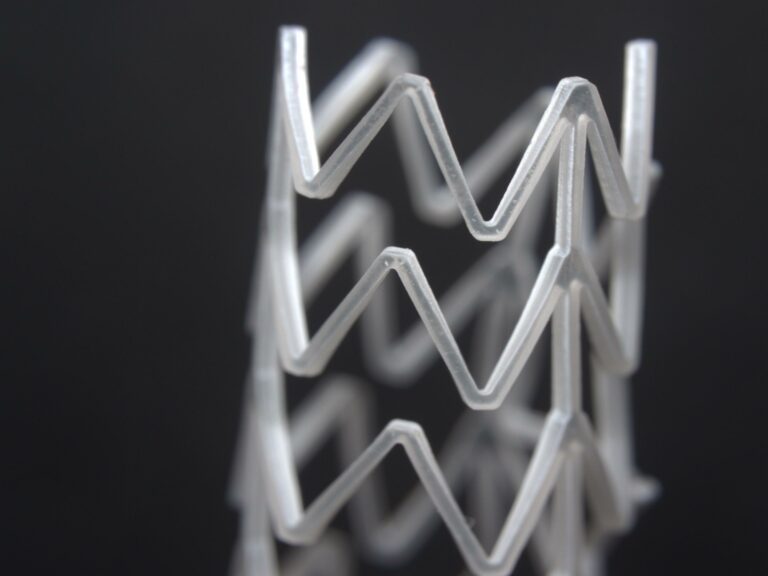

A recent report from the World Health Organization (WHO) identified that heart disease is the leading cause of death globally and that the rate of heart disease cases is rapidly increasing. In order to treat heart disease one of the most common treatments is to implant a small device, called a vascular

stent, to maintain blood flow.

Stents have evolved significantly in the past two decades and many of them are manufactured by laser cutting and laser welding. In this article we investigate the different types of materials used in stents and how a single laser source can be used to machine all of the necessary materials.

The Stent – Miniature Device Saving Lives

Since the advent of the vascular stent, heart disease has been successfully treated with minimally invasive surgery. According to reports, more than 965,000 angioplasties are performed each year in the USA alone, in this procedure a balloon is used to inflate the blood vessel – often this is accompanied by the insertion of a stent, in which case the procedure is known as Percutaneous Coronary Intervention (PCI).

Materials for Stents

As stents are implanted in the body, there are a variety of requirements that must be met. Firstly, it is essential that they are made from a bio-compatible material which will not cause a reaction with tissue and blood. Secondly, stents are implanted for long periods of time and thus they must be resilient and durable. Finally, stents require high precision processing so that they are fit for purpose and do not accumulate debris.

Traditionally, metals have been used with the most common being stainless steel, nitinol (a nickel titanium alloy with shape memory) or cobalt chrome alloys. These materials have high wear resistance, high impact strength, ductility and the capacity to absorb force well.

Another technique to ensure long term efficacy is to use a stent which has suitable mechanical properties but gradually dissolves in the artery – these are known as bioabsorbable (or bioresorbable) stents. Typically, these are either made from magnesium alloys that 95% dissolve harmlessly in situ, or alternatively they are made from polymers like Polylactic Acid (PLA) and similar materials.

Laser Manufacturing of Stents

Over the years, many methods of manufacturing stents have been developed, such as braiding (sometimes joined with laser welds) micro-injection molding, 3D printing or laser cutting, but only the latter meets the demands of high precision in both polymer and metal structures.

One Source for all materials

When manufacturing stents by laser cutting, the highest demands on geometrical repeatability, rapid throughput and minimum post-processing are all significant. Given the different types of materials used (both metallic and plastic) there are distinct advantages in having one source which can cut multiple materials – to minimize the cost of production machinery.

One of the main advantages of laser cutting with ultrashort pulses (for example femtoseconds) is that there is virtually no heat input which avoids the heat affected zone (HAZ) area in metals and also the melting of heat-sensitive polymers. The interaction time of a femtosecond pulsed laser is much shorter than the thermal diffusion time, which results in cold ablation cutting rather than thermal cutting – a much cleaner and more precise solution for all materials.

The Jasper X0 from Fluence Technology is a femtosecond laser with the combination of short pulse, high energy peak and customizable repetition rate that makes this application successful. Recent testing in the Fluence Ultrafast Laser Application Laboratory (ULAL) has investigated many applications, including one of the most challenging, the fabrication of stents made of thermally sensitive biodegradable PLA.

Two methods of material processing using ultrafast lasers are the dicing method and the laser ablation method. Each have their own benefits, and ultrafast lasers provide capability to both methods, which are explained in the following sections of this paper.

Conclusion

Vascular and non-vascular stents enable serious medical conditions to be treated with minimal invasive surgery, and are made from durable bio-compatible materials requiring precise laser machining to manufacture. Ultrafast pulsed lasers utilize precise bursts of light to cut stents smoothly and to extremely high tolerances, and they improve implant integration via laser surface patterning. Femtosecond lasers are used to manufacture metal stents and are the only solution for polymer stents. Femtosecond lasers enable high throughput and maximum flexibility, making them the preferred tool for stent manufacturers regardless of material.