16.10.2023

16.10.2023

A Novel Technology in Femtosecond Laser Processing of Ultra-Thin Glass and Polymers

The flexible tuning of laser parameters plays a pivotal role in cleaving diverse materials. The use of ultrafast femtosecond fiber lasers enables a significantly higher quality and enables easy polymer cleaving more efficient process, opening new possibilities for a wide range of applications.

Redefining Ultra-Thin Glass Processing

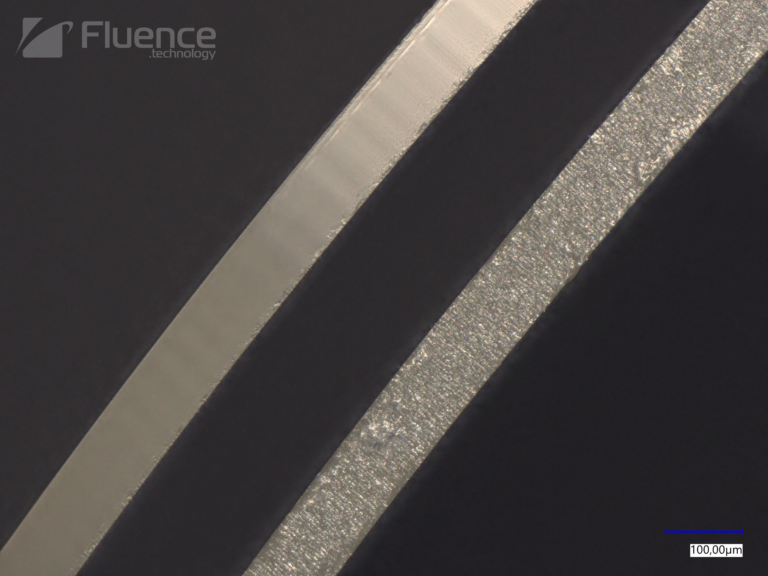

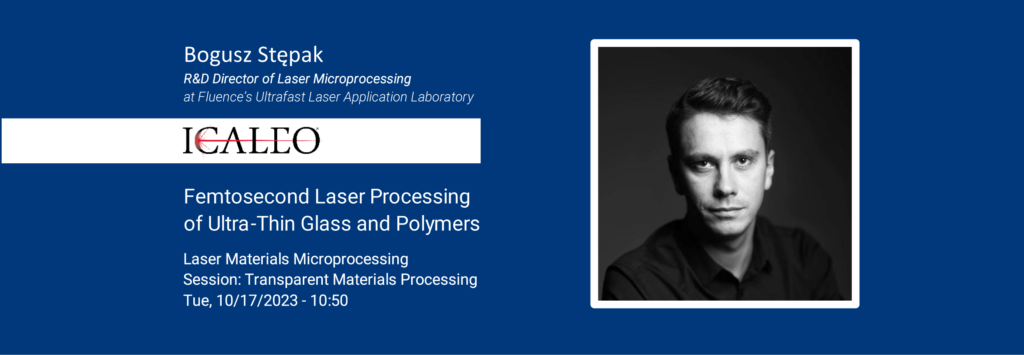

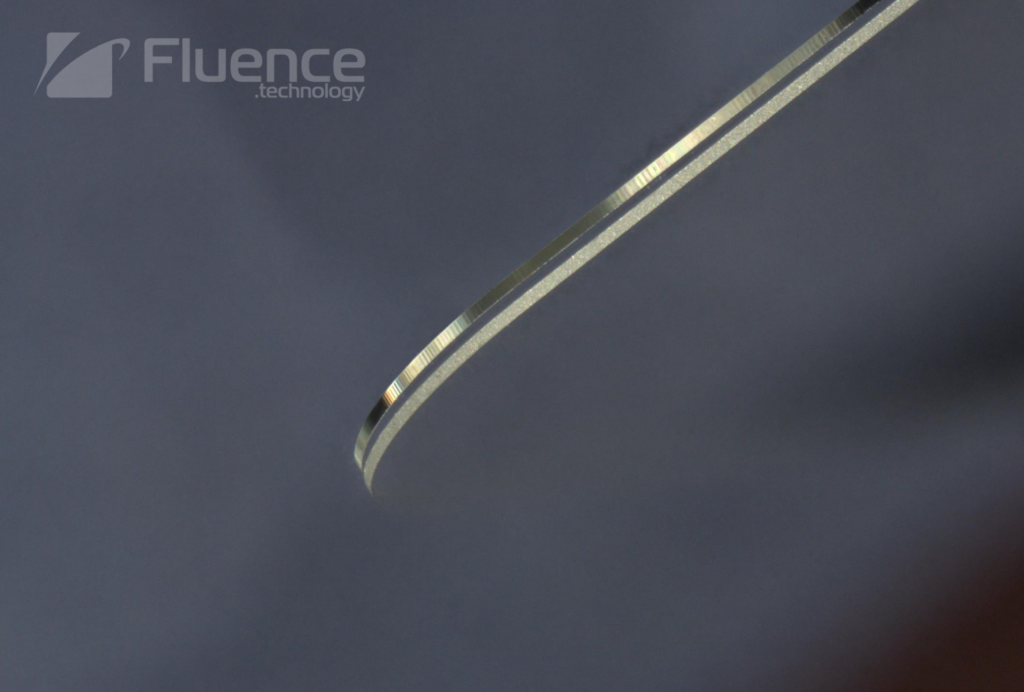

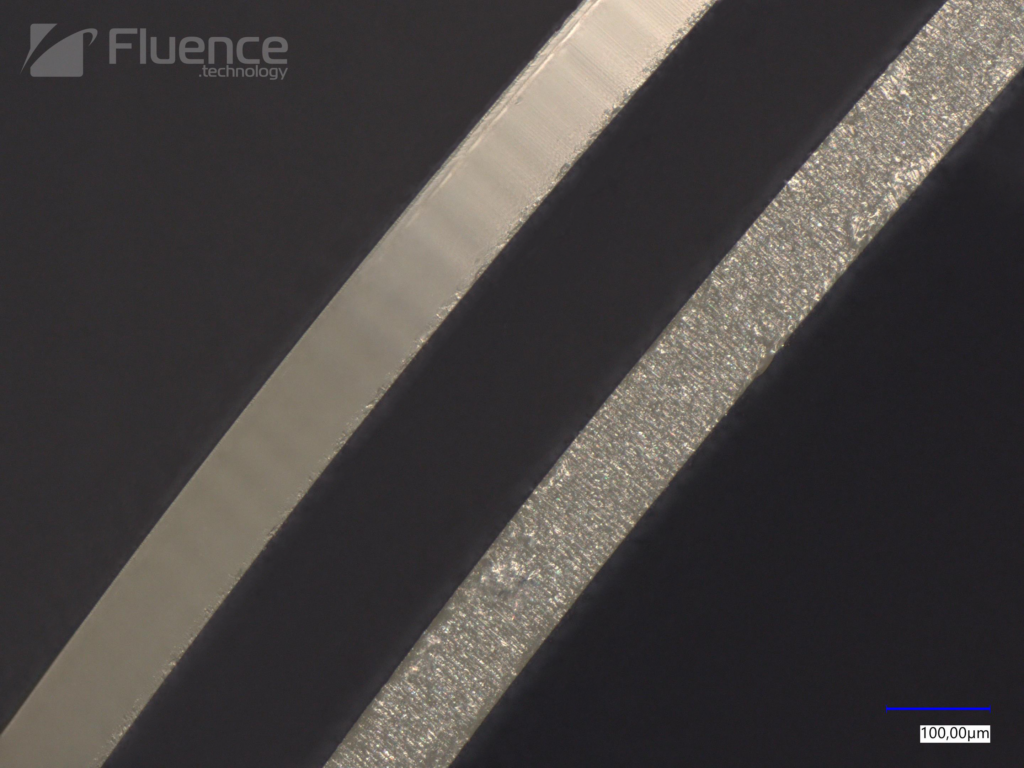

The innovative approach to Ultra-Thin Glass (UTG) processing has been the subject of extensive research at the Ultrafast Laser Application Laboratory (ULAL) for last months. On October 17th, during the ICALEO conference, Bogusz Stępak, the R&D Director of Laser Microprocessing at Fluence’s ULAL, will share the remarkable results of their investigations. These results not only encompass a variety of beam quality parameters but also compare the edge produced by femtosecond processing with the commonly used picosecond pulse for glass cutting. Surface roughness analysis demonstrates a significant advantage in cutting 100 μm glass with femtoseconds, providing a fivefold reduction in edge roughness (Sa < 100 nm) compared to picoseconds.

“This level of edge precision can be of immense importance, particularly when dealing with delicate materials such as UTG used in foldable displays“, says Bogusz. Microcracks resulting from suboptimal processing parameters can lead to reduced screen longevity due to increased susceptibility to breakage. Utilizing the glossy-cut edge significantly enhances the quality of the produced screens.

“Furthermore, we have applied a similar method to medical-grade PLA polymer cutting, which is new in the field. Shaped beam of femtosecond laser allows for the processing of transparent, as well as hazy, crystallized polymers, without the Heat Affected Zone (HAZ), which is essential for biomedical applications” – Bogusz continues.

For a closer look at our innovative methods for UTG and polymer cutting, we invite you to join us at the Palmer House Hilton in Chicago, IL, USA, from October 16th to 19th, during the ICALEO conference.

Katarzyna Kowalska, 2023-10-16